- The main reasons for the month on month decline in PPI are:

One is the impact of international input factors on the price decline of domestic related industries. The decline in international crude oil prices has affected the prices of domestic petroleum related industries, with prices in the oil and gas extraction industry falling by 5.6%, refined petroleum product manufacturing prices falling by 3.5%, and chemical raw material and chemical product manufacturing prices falling by 1.2%. The total impact of these three industries on PPI decreased by about 0.23 percentage points month on month, accounting for more than 50% of the total decline.

The second is the periodic decline in prices of some domestic energy and raw materials. Coal demand is in the off-season, with sufficient coal reserves in power plants and ports. In addition, the low cost and strong substitution effect of new energy power generation have led to a 3.0% decrease in coal mining and washing industry prices, and a 1.1% decrease in coal processing prices. The increase in hot and rainy weather in the southern region has affected the construction of some real estate and infrastructure projects. In addition, the production and supply of building materials such as steel and cement are sufficient, and the prices of black metal smelting and rolling processing industry and non-metallic mineral products industry have all decreased by 1.0%. The total impact of the above four industries on PPI has decreased by about 0.18 percentage points compared to the previous period.

Due to factors such as the increase in the year-on-year comparison base, the year-on-year decline in PPI has expanded by 0.6 percentage points compared to the previous month. However, from the perspective of marginal changes, China’s macro policies have been strengthened, and the supply-demand relationship in some industries has improved, while prices in some areas are showing a positive trend.Firstly, the continuous growth of new consumption drivers has led to a year-on-year rebound in prices of daily necessities and other necessities. The policies related to boosting consumption continue to be effective, and the release of demand for some consumer goods has driven the price recovery of related industries. The prices of daily necessities decreased by 0.2% month on month to remain stable, with clothing, general daily necessities, and durable consumer goods prices rising by 0.2%, 0.1%, and 0.1% respectively, driving the year-on-year decline in prices of daily necessities to narrow by 0.2 percentage points compared to the previous month. From the perspective of the industry, the manufacturing prices of arts and crafts and etiquette supplies increased by 12.8% year-on-year, the footwear industry increased by 0.8%, the manufacturing prices of computer machines increased by 0.2%, and the manufacturing prices of household washing machines, televisions, and automobiles narrowed by 1.6, 1.4, and 0.6 percentage points respectively compared to the previous month.

Secondly, the development of high-end equipment manufacturing and other industries has driven up prices in related industries year-on-year. The transformation of industries towards high-end, intelligent, and green development is steadily advancing, and the demand for high-tech products is expanding, resulting in a year-on-year increase in prices in related industries. The prices of integrated circuit packaging testing series and aircraft manufacturing have both increased by 3.6%, wearable smart device manufacturing prices have increased by 3.0%, microwave communication equipment prices have increased by 2.1%, server prices have increased by 0.8%, and semiconductor device specialized equipment manufacturing prices have increased by 0.7%. In addition, the supply and demand relationship of new energy industries such as photovoltaics and lithium batteries has improved, and the year-on-year price decline has narrowed. The prices of photovoltaic equipment and component manufacturing and lithium-ion battery manufacturing have decreased by 12.1% and 5.0% respectively, with a decrease of 0.4 and 0.3 percentage points compared to the previous month.

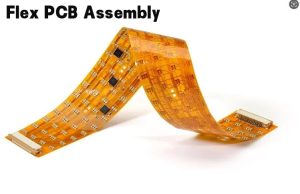

Flex PCB Assembly: A Complete Guide for Modern Electronics

From consumer electronics to medical devices and automotive systems, flexible printed circuit boards (Flex PCBs) enable innovative product structures that rigid PCBs cannot achieve. What